Reel-to-Reel Audio Tape Manufacturers

By Jesse Acorn

As someone who repairs, sells, and makes frequent use of reel-to-reel tape recorders, I am often asked what options exist for new tape. Below, I have compiled a list of all contemporary tape manufacturers and the types of tape they produce, to the best of my ability. As with my Vacuum Tube Manufacturers article, I have tried to identify the actual factories, indicating who truly makes tape and who merely distributes it. Because certain companies have been uncommunicative or dishonest, I have had to speculate about the origin of certain tapes. My list is current as of June 2024; I will update it occasionally. A few initial notes:

- Base thickness is approximate, rounded to the industry standards of 1 or 1.5 mil. Other thicknesses are exact.

- My recommended operating level (R.O.L.) is the tape's remanence fluxivity level relative to Scotch 111 rounded to the nearest multiple of 3dB, as per industry standard.

- Question marks indicate that the info is not public, nor could I obtain it from direct correspondence with the company. I cannot calculate R.O.L. without oxide thickness and retentivity.

I. Factories

- Astrum / Svema in Shostka, Ukraine

| Type: | Widths (in): | Base (mil): | Oxide Coating (µm): | Back Coating (µm): | Coercivity (Oe): | Retentivity (Gs): | My R.O.L.: |

| А4620-6Р | ¼ | 1.5 | ? | ? | ? | ? | ? |

| Б3715 | ¼ | 1 | ? | none | ? | ? | ? |

| ? | 1 | 1.5 | ? | none | ? | ? | ? |

- Founded in 1995.

- Obtained tape production equipment from former Soviet factory Svema (Свема), which went bankrupt and shut down in 2015. Astrum's tape is branded Svema; they acquired the trademark.

- Besides their website, they also sell tape through their all.biz account. Neither site lists any audio types, so my list is based on info from a post here, and my correspondence with the company.

- Also makes various tapes for non-audio purposes in the В (computer) and И (instrumentation) series. Another former Soviet manufacturer, Slavich (Славич), also still exists and manufactures magnetic tape, but nothing intended for audio, which I have confirmed by email.

- ATR Magnetics in York, Pennsylvania, USA

| Type: | Widths (in): | Base (mil): | Oxide Coating (µm): | Back Coating (µm): | Coercivity (Oe): | Retentivity (Gs): | My R.O.L.: |

| Master Tape | ¼, ½, 1, 2 | 1.5 | 12.7 | 0.8 | 330 | 1400 | +6dB |

| MDS-36 | ¼ | 1 | 12.7 | 0.8 | 330 | 1400 | +6dB |

- Founded in 2005 by Michael D. Spitz, a former employee of Ampex, in response to closure of the Munich BASF/AGFA plant in 2004, and spurred on by Quantegy's closure in January 2005. Started shipping tape by late 2007.

- Master Tape specs have been significantly changed at least twice. Before late 2017, it was marketed as "a reincarnation of the high output, low distortion tapes of the past but with even higher coating thickness [...]". Their datasheet from 2009 shows higher magnetic specs than now (365 Oe, 1590 Gs), and indeed a much thicker oxide coating (18.5µm), resulting in 9.1dB remanence fluxivity level relative to Scotch 111. This means that it was a "+9dB" tape; today's specs give 4.7dB remanence, which is just barely high enough to call it "+6dB". By January 2012, oxide thickness spec was reduced to 15.0µm, but magnetic specs stayed the same, giving +7.3dB remanence. By 2020, the current specs were published, further reducing magnetic parameters and oxide thickness. Note that approximate ideal bias decreased 4.1dB from the early specs to the current specs, so if the numbers are right, early and current tapes are not bias-compatible. When I asked if they changed their tape design (before I found the Wayback Machine pages linked above), ATR claimed that Master Tape was "+6" from the beginning. After being presented with this evidence, they never responded.

- MDS-36 was introduced in 2016, and its specs were originally the same as Master Tape except base thickness, hence its specs also changed by 2020.

- Like Ampex and Quantegy, their tape is slit narrow, with all nominal widths 4 mils below proper values; for instance, their ¼" tape is specified as 0.246". Tolerance is not stated on their current datasheet, but a 2009 sheet says +0.0 / -2.0 mils. This allows good performance in heads worn by Ampex/Quantegy tapes, but if a fresh slotless head wears to their tapes, a properly slit tape will ride up on one or both edges, potentially causing poor high-frequency response or edge shaving.

- Also produces graphite-lubricated tape for continuous loop applications (tape echos, cartridges, etc.) with no technical specs provided.

- Greencorp in Matraville, New South Wales, Australia

| Type: | Widths (in): | Base (mil): | Oxide Coating (µm): | Back Coating (µm): | Coercivity (Oe): | Retentivity (Gs): | My R.O.L.: |

| BR Pro* | ¼, ½ | 1 | 9.0 | 3.0 | ? | ? | ? |

| BR Pro* | ¼, ½ | 1.5 | 9.0 | 3.0 | ? | ? | ? |

| BR Master* | ¼, ½ | 1 | 13.0 | 3.0 | ? | ? | ? |

| BR Master* | ¼, ½ | 1.5 | 13.0 | 3.0 | ? | ? | ? |

| Darklab PE3035Mᵃ | ¼ | 1 | ? | ? | ? | ? | ? |

| Darklab PE5055Mᵃ | ¼ | 1.5 | ? | ? | ? | ? | ? |

| QMG Grand Master | ¼, ½ | 1 | 9.0 | 3.0 | 360 | 1300 | 0dB |

| Splicit Capture 914 | ¼, ½ | 1.5 | 9.0 | 3.0 | 360 | 1300 | 0dB |

| Splicit Capture 930 | ¼, ½ | 1 | 9.0 | 3.0 | 360 | 1300 | 0dB |

- Distributed by Splicit of Oregon, USA under the "Capture" brand starting in 2016, and Classic HiFi Australia under the "QMG Grand Master" brand starting in 2022. These companies are honest about where their tapes come from.

- Splicit briefly offered Capture 918 in 2020 through Duplication.ca and Burlington Recording. It was marketed as a 1.5 mil +6dB tape, but was never announced on Splicit's website, and has not remained in production.

- * Burlington Recording/AnalogTapes.com of Florida, USA denies that Greencorp makes their house-brand "Pro" and "Master" series tapes introduced in 2023 (saying that they come from Europe, but refusing to name the country), so it is only speculation that their tapes come from Greencorp. However, there is considerable evidence that they do, including the following:

- ᵃ Darklab Magnetics of Solingen, Germany—who introduced their tapes in 2022—never responded to an inquiry, and has claimed that they come from England, so it is only speculation that their tapes come from Greencorp. However, they have the typical Greencorp white paper hold-down label and NAB core, and are priced in line with the rest.

- Greencorp refused to answer any questions about their tapes whatsoever.

- Recording the Masters in Avranches, France

| Type: | Widths (in): | Base (mil): | Oxide Coating (µm): | Back Coating (µm): | Coercivity (Oe): | Retentivity (Gs): | My R.O.L.: |

| LPR35 | ¼ | 1 | 11.0 | 4.5 | 320 | 1450 (corrected) | +3dB |

| LPR90 | ¼ | 1 | 11.0 | 4.5 | 370 | 1540 | +3dB |

| SM900 | ¼, ½, 1, 2 | 1.5 | 17.5 | 3.0 | 370 | 1540 | +9dB |

| SM911 | ¼, ½, 1, 2 | 1.5 | 16.0 | 4.0 | 320 | 1450 | +6dB |

- Their lineage can be traced back to Agfa and BASF/EMTEC in Munich, Germany; RMGI in Oosterhout, Netherlands (originally a Philips factory established in 1968); and Pyral in Avranches, France.

- Types LPR35, SM468, SM900, and SM911 were produced by BASF/EMTEC until 2004, when they transferred equipment and personnel to RMGI, who resumed production. Pyral was established in the early 20th century, in 1934 invented the "acetate" lacquer recording disc, and for decades manufactured perforated magnetic film for motion picture and television use. RMGI shut down in 2012, transferring tape production to Pyral, who went bankrupt in late 2013. Pyral was sold to Mulann in 2015, resuming production, and in early 2016, their brand was changed to Recording the Masters (RTM). Their parent company has changed several times since.

- LPR90 was introduced in 2016, ostensibly as a 1 mil version of SM900, though its oxide coating is thinner, and consequently it has lower maximum output and ideal bias.

- SM468—the only RTM type developed by Agfa, originally called PEM468—was discontinued in 2021. It is a low-print-through archival tape marketed by RTM as having +3dB R.O.L. (to round out their 1.5 mil lineup, I presume), but it was actually a +6dB tape, as shown on Jay McKnight's tape info table, considering its remanence is 5.9dB above Scotch 111. This is slightly lower than SM911 (7.1dB), but SM468 has slightly higher ideal bias due to significantly higher coercivity (380 Oe) yet not proportionally thinner oxide (14.5µm).

- RTM tape is properly slit with tolerance of +0.0 / -2.4 mils, meaning that their tapes will ride up on one or both edges of slotless heads worn to Ampex/Quantegy or ATR tape, since those are intentionally slit 4 mils narrow.

- Shenzhen Modo Technology Co. in Shenzhen, China

| Type: | Widths (in): | Base (mil): | Oxide Coating (µm): | Back Coating (µm): | Coercivity (Oe): | Retentivity (Gs): | My R.O.L.: |

| KL900 | ¼, ½ | 1.5 | 16.0 | 4.0 | 320 | 1450 | +6dB |

- Founded in 2005, 2009, or 2011 (depending which part of their Alibaba page or website you read) producing VHS and audio cassettes.

- Started producing ¼" reel-to-reel tape in early 2022.

- KL900 is a copy of SM911, based on these specifications sent to me (which are pages of the old RMGI datasheet with "KL900" pasted over "SM911").

- Might be the same as the "ORT" tape distributed by Burlington Recording/AnalogTapes.com of Florida, USA under the "CMC Magnetics" brand, and Reel-to-Reel Tech of British Columbia, Canada under their house brand, though neither company would divulge their sources, so this is speculation. Here is my evidence:

- CMC Magnetics and Reel-to-Reel Tech tapes are the same because all physical and technical features are identical, including the NAB core, translucent white plastic hold-down strip, and box labeling (see Burlington's box here; they removed the picture since I first wrote this, replacing it with their "CMC Magnetics" logo, which is an imitation of the old RTM logo).

- Shenzhen Modo tape exhibits the same style of writingless hold-down strip, and they have told me that that they sell black NAB cores, but I have not found pictures.

- Reel-to-reel tech informed me that ORT tape is "modeled after SM911", Burlington claims it is bias-compatible with SM911, and it is 1.5 mil. All true of KL900.

- Both Burlington and Reel-to-Reel Tech say that their tape is made in China. Shenzhen Modo is the only Chinese reel-to-reel tape manufacturer that I know of (and even so, I can't be sure that they aren't just a distributor). However, a Chinese business called CFK Trading Company was selling reel-to-reel tape in mid 2023 with the same style of NAB core. Based on their name, I presume they are merely a distributor; they have no online presence, and I have not found any contact info. Note that Burlington sells cassettes with the CFK brand name, indicating a connection.

- Burlington's brand, "CMC Magnetics", has no relation to the company of the same name in Taiwan, instead chosen in reference to Cassette Magnetics Corp. of Brooklyn, NY, which operated from 1970 to 1973 and was owned by Rudy Schwartz, founder of Burlington Audio Tapes and father of the current owner, Jan.

II. Understanding Tape Properties

In this section, I hope to give enough technical information for you to understand my tape comparisons in the next section. It is assumed that you have some basic knowledge of tape recording and scientific concepts. If you want a more detailed understanding than what I have provided below, I suggest looking at the "Recommended Reading" list at the bottom of the page, particularly noting the old books.

I will start with physical structure. With the exception of some very early tapes, all tapes exhibit layered construction, with a plastic base material onto which an oxide coating and sometimes a carbon back-coating are applied. Good diagrams can be found in this article. Physically, these are the most important properties of tape:

- Width — ¼", ½", 1", and 2" are standard.

- Base material — Polyester is the only material in current use. Cellulose acetate (usually shortened to just "acetate"), PVC, and paper have been used in the past, but the stability and durability of polyester is highest. Acetate has the benefit of snapping cleanly under high tension, meaning it can be spliced without loss of program material, whereas polyester stretches. However, acetate is chemically unstable, often exhibiting "vinegar syndrome" and deforming if stored in poor conditions.

- Base thickness — approximately 1 and 1.5 mils are standard; the former is called "long play", while the latter is "standard play". In the past, 0.5 mil tapes were made in "double play" and "triple play" forms, but these are generally avoided today due to their fragility and low output.

- Oxide coating thickness — the thickness of the magnetic coating. Note that the oxide particles are not merely glued to the backing like grains of sand on sandpaper, but suspended in a matrix of binder glue, with only some particles sticking out. To reduce abrasiveness further, the surface of the coating is polished, and a dry silicone lubricant is added to the binder.

- Back coating thickness — the thickness of the back coating, which is usually carbon black, matte, and slightly electrically conductive. Not all tapes are back-coated, but most professional tapes have been since the introduction of Scotch 206 and 207 in 1969. Such a coating improves evenness of tape packing (especially during fast-winding), dissipates static electricity, and reduces print-through. It also increases friction with the pinch roller or capstan, which means higher abrasiveness than an uncoated base.

Magnetically, the oxide coating has two fundamental properties, which are independent of the physical properties listed above:

- Retentivity — The magnetic flux density B remaining in the material after it has been saturated (all magnetic domains aligned) and the magnetizing force H has been removed. It is measured in teslas (T) or gauss (G or Gs), and can be thought of as how strongly the material can become magnetized.

- Coercivity — The magnetizing force H required to reduce the magnetic flux density B of the material to zero, after it has been saturated and the magnetizing force has been removed. It is measured in oersteds (Oe) or amperes per meter (A/m), and can be thought of as how strong a field it takes to magnetize the material.

Coercivity and retentivity are affected by the chemical composition of the oxide particles, as well as the average length, shape, and distribution of these particles. This explains how, despite that nearly all reel-to-reel audio tapes use gamma iron oxide particles, coercivity varies from about 260 to 380 Oe, and retentivity from about 900 to 1700 Gs.

Another important magnetic concept is fluxivity, which is defined as magnetic flux per unit width of tape, and is typically measured in nanowebers per meter (nWb/m). Because it is a measure of absolute flux per unit width, not flux density, it is thus proportional to the output from a given play head at a given frequency. In other words, it is the amplitude of the magnetic signal on tape. There are two especially important fluxivity values:

- Remanence fluxivity (which I usually shorten to "remanence") — the magnetic flux per unit width of tape after it has been saturated and the magnetizing force has been removed. This is the peak fluxivity. As per Jay McKnight's tape info table, it is the product of oxide coating thickness in µm and retentivity in mT, which gives a result in nWb/m.

- Reference fluxivity — the chosen fluxivity at which the tape machine's volume indicator reads 0dB, and its output voltage is at reference level (typically either -10 dBV, 0 dBu, or +4 dBu). This is an RMS value rather than a peak value, and it varies with frequency because of the equalization applied to the signal before and after it is recorded to tape. The original standard is 185 nWb/m at 700 Hz (or 180nWb/m at 1 kHz), which was chosen for early tapes like Scotch 111. For tapes with higher remanence, reference fluxivity can be higher while giving the same amount of headroom. The standard reference fluxivity values are 185, 260, 370, and 520 nWb/m at 700 Hz, which correspond to levels of 0, +3, +6, and +9 dB respectively.

By comparing a particular tape's remanence fluxivity to the 1030 nWb/m of Scotch 111, you can determine its recommended operating level. This is the reference fluxivity (expressed as a level in dB relative to 185 nWb/m at 700 Hz) at which the tape gives the same headroom as Scotch 111 used at "0dB". For instance, Ampex 456 has remanence 5.6dB above Scotch 111, allowing a reference fluxivity 6dB higher than 185 nWb/m while having the same amount of headroom. This is why it is called a "+6dB" tape. Why increase reference fluxivity? Because it reduces tape hiss relative to the program material; the noise floor is lowered.

It is not strictly necessary to record at the recommended level. In fact, MRL's "Choosing and Using" paper suggests a reference fluxivity 3dB lower than normal when using a noise reduction system such as Dolby or DBX, since these allow you to record at lower levels to increase headroom without proportionally increasing noise. However, if your reference level is far off, there may be excessive distortion at normal meter indication, or excessive noise caused by low recording amplitude.

Similar to remanence, approximate ideal bias can be calculated as the product of coating thickness and coercivity, as per McKnight's table. In my comparisons, I have stated it in decibels relative to the 3035 Oe-µm of Scotch 111 using the formula for root-power quantities. In practice, bias is not normally adjusted relative to a standard level, but instead by recording tones and measuring change in playback amplitude. Tapes with different ideal bias cannot be interchanged while maintaining best recording performance; distortion and high-frequency response will be affected. However, ideal bias has no relevance to playback, since bias is only applied during recording.

In general, coercivity and retentivity increase together, so ideal bias and remanence usually go hand in hand too. However, this is not a rule, since it is possible to have a tape with relatively low coercivity and high retentivity or vice versa. For instance, chromium dioxide tapes (which were made in low quantities in the '70s and '80s) have very high coercivity of about 500 to 700 Oe—about double iron oxide tapes—yet comparable retentivity, meaning they require much higher bias, yet give similar output. Thus, it is false and misleading to say that a tape needs, say, "+6dB bias" when referring to its output. This is the recommended operating level, not the bias level. Tapes with the same R.O.L. can be have different ideal bias to the point of being bias-incompatible.

Lastly, I should try to explain headroom in tape recording. By its usual definition, headroom is the amount of signal above a certain reference that a system can handle without trouble (which usually comes in the form of excessive distortion). In digital systems, headroom is easily quantified, since the signal is virtually undistorted until it reaches saturation, at which point the peaks are squared off and lost (i.e. "clipped"). Headroom there is simply the difference between the maximum undistorted signal level and the reference level. This is also true in many analog systems, especially from the 1970s and later, which are designed with op-amps, or otherwise use a large amount of negative feedback to give extremely low distortion prior to "clipping". However, in tape recording, headroom is not so easily quantified, since the onset of distortion is quite gradual. This is an unavoidable result of the tape's magnetic properties, which can be understood from its B-H curves—aka hysteresis loops—that relate the magnetic force applied to the tape to its resulting magnetization.

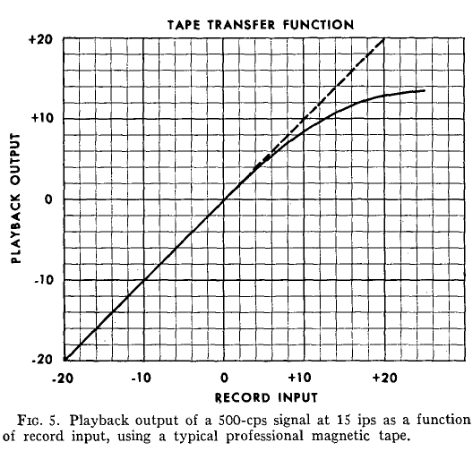

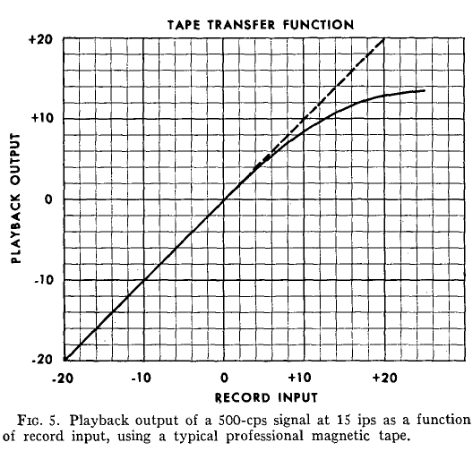

We can try to quantify headroom anyway using several approaches. One is to subtract the saturation fluxivity (which is the RMS value of remanence assuming linear behavior of the tape, which is not actually true but "good enough") from the reference fluxivity. When the recommended operating level is used, the difference for any given tape is roughly 12dB at 700 Hz. For instance, the saturation fluxivity of SM900 is 2695/sqrt(2) = 1905 nWb/m, which is 20.2 dB above 185 nWb/m, and therefore 11.2 dB above the tape's "+9" recommended operating level. You might say, "this means that there is about 12dB of headroom", but that is misleading, since it doesn't take into account how gradually the tape saturates. Here is a diagram from a 1963 paper called Intermodulation Distortion in Tape Recording by Robert Langevin, which shows the transfer function of a typical tape:

Notice that the amplitudes begin to diverge at only 4dB above reference, and complete saturation is reached when the input is around +26dB, while the output is around +14dB (which is the "roughly 12dB" output level mentioned earlier). This divergence is caused by increasing output distortion, and it constitutes the so-called "tape compression" effect. To be clear, this effect is actually soft distortion, and is frequency-dependent, since the equalization used in audio recording causes high frequencies to saturate first. This can sound quite pleasant; it can enhance a recording if carefully used. At low speeds, this effect is especially pronounced, as shown in the plots on page 3 of the SM900 datasheet.

What does this mean for headroom? The onset of what by some definitions could be called "significant" distortion is only about 4dB above reference level, yet true saturation is only reached 26dB above reference. Likely the best approach to quantifying headroom on tape is to subtract, from the reference level, the level at which a particular signal is distorted by a certain amount. Choosing this level is rather arbitrary, but a reasonable metric could be, say, when a 1 kHz tone develops 5% total harmonic distortion.

III. Comparison

Below is a list of tape stocks for which adequate data has been provided to determine remanence and approximate ideal bias. I hope that information for other tapes will be published in the future, especially those from Astrum and Burlington, so that I may increase the completeness of my comparisons.

Keep in mind that data is subject to change, and that all parameters have a tolerance; for instance, RTM has told me that their oxide thickness tolerance is ±0.5µm. Incidentally, I have found RTM the most communicative, helpful, and pleasant company of all by a significant margin, and they have also provided corrections to the data for LPR35, LPR90, and SM900, hence why these values are not entirely the same as those on their datasheets (which are somewhat questionable, I must admit).

| Factory: | Type: | Base (mil): | Oxide (µm): | Widths (in): | Coercivity (Oe): | Retentivity (Gs): | Remanence (nWb/m): | ~Bias: |

| ATR | Master Tape | 1.5 | 12.7 | ¼, ½, 1, 2 | 330 | 1400 | 1778 / 4.7dB | 2.8dB |

| ATR | MDS-36 | 1 | 12.7 | ¼ | 330 | 1400 | 1778 / 4.7dB | 2.8dB |

| Capture | 914 | 1.5 | 9.0 | ¼, ½ | 360 | 1300 | 1170 / 1.1dB | 0.6dB |

| Capture | 930 | 1 | 9.0 | ¼, ½ | 360 | 1300 | 1170 / 1.1dB | 0.6dB |

| QMG | Grand Master | 1 | 9.0 | ¼, ½ | 360 | 1300 | 1170 / 1.1dB | 0.6dB |

| RTM | LPR35 | 1 | 11.0 | ¼ | 320 | 1450 | 1595 / 3.8dB | 1.3dB |

| RTM | LPR90 | 1 | 11.0 | ¼ | 370 | 1540 | 1694 / 4.3dB | 2.5dB |

| RTM | SM900 | 1.5 | 17.5 | ¼, ½, 1, 2 | 370 | 1540 | 2695 / 8.4dB | 6.6dB |

| RTM | SM911 | 1.5 | 16.0 | ¼, ½, 1, 2 | 320 | 1450 | 2320 / 7.1dB | 4.5dB |

| Shenzhen Modo | KL900 | 1.5 | 16.0 | ¼, ½ | 320 | 1450 | 2320 / 7.1dB | 4.5dB |

First, I will sort the tapes into remanence classes by rounding each remanence level to the nearest multiple of 3dB. In the "0dB" class, we have those Greencorp tapes for which data has been published, namely Capture 914 and 930, as well as QMG Grand Master. Note that these are indeed closest to 0dB in both remanence and ideal bias, despite that they are marketed as "+3dB" tapes. To me, this is good news, because I value low-output tapes for their ability to saturate easily, and my favorite tape recorders are early machines designed for such tapes. In the "+3dB" class, we have only RTM's LPR35 and LPR90, which are both 1-mil. The "+6dB" class includes ATR's tapes, RTM SM911, and Shenzhen Modo KL900. The only tape in the "+9dB" class is RTM SM900.

Note that ATR and Greencorp produce pairs of tapes with different base thickness yet identical magnetic properties and coating thicknesses. Except in maximum running time and robustness, these tapes should perform equivalently. Conversely, the pairs of RTM tapes that are said to be the long-play or standard-play versions of one another are rather different in performance. LPR90 and SM900 have the same oxide formulation, but the difference in oxide thickness causes 4.1dB of difference in both remanence and ideal bias. For LPR35 and SM911, this difference is 3.3dB. While a 3dB difference in remanence is difficult to hear, a bias difference of 3dB can cause roughly 3dB of response change at 10 kHz (and even more above this frequency) at 7.5 ips, which is easily audible. This means that, at least where equivalent performance matters, and especially at low speeds, LPR35/SM911 and LPR90/SM900 should not be considered interchangeable.

We can group the tapes similarly in terms of approximate ideal bias. Because of how drastically bias affects high-frequency performance, I have used multiples of 1.5dB, which is the largest difference for me to consider tapes "bias-compatible". The results are similar but not identical to remanence groupings. LPR35 and LPR90 are no longer in the same class, and ATR's tapes are in the same class as LPR90. Note that this kind of grouping is not normally done, since differences in head design and bias frequency mean that bias is not set relative to a standard amplitude (as with operating level), but instead by measuring change in playback level. Nonetheless, it can be useful to consider the relative differences in bias. Below are the tabulated results of my sorting:

| Factory: | Type: | Remanence class: | Bias class: |

| ATR | Master Tape | 6dB | 3dB |

| ATR | MDS-36 | 6dB | 3dB |

| Capture | 914 | 0dB | 0dB |

| Capture | 930 | 0dB | 0dB |

| QMG | Grand Master | 0dB | 0dB |

| RTM | LPR35 | 3dB | 1.5dB |

| RTM | LPR90 | 3dB | 3dB |

| RTM | SM900 | 9dB | 6dB |

| RTM | SM911 | 6dB | 4.5dB |

| Shenzhen Modo | KL900 | 6dB | 4.5dB |

Let us now move on to basic physical properties—for which we can consider all tapes from all makers—starting with width. Tapes of ¼" width are produced by all manufacturers, and every tape except Astrum's mystery 1" type is produced in ¼" width. Tapes of ½" width are made by all except Astrum. The only manufacturers of 2" tape are ATR and RTM, and Astrum is the only additional manufacturer of 1" tape. Below is a table listing the number of tape types for each width, along with what types these are.

| Width (in): | # of Types: | Types: |

| ¼ | 16 | Astrum А4620-6Р and Б3715; ATR Master Tape and MDS-36; BR Pro and Master; Darklab PE3035M and PE5055M; QMG Grand Master; Splicit Capture 914 and 930; RTM LPR35, LPR90, SM900, and SM911; Shenzhen Modo KL900 |

| ½ | 9 | ATR Master Tape; BR Pro and Master; QMG Grand Master; Splicit Capture 914 and 930; RTM SM900, and SM911; Shenzhen Modo KL900 |

| 1 | 4 | Astrum mystery; ATR Master Tape; RTM SM900 and SM911 |

| 2 | 3 | ATR Master Tape; RTM SM900 and SM911 |

All tapes have a polyester base. There are no contemporary manufacturers of acetate, PVC, or paper tapes, but I can think of no problems with this, because polyester is more resilient and long-lasting than any of these materials. Strangely, my Capture 914 and 930 tapes pass light when viewed from the side, which is normally a reliable indicator of acetate base. However, under high tension, Capture tape stretches like polyester instead of snapping like acetate, so I trust that it is indeed polyester.

Except Astrum's Б3715 and mystery 1" tape, all tapes have a matte black back-coating. The higher abrasiveness of this coating relative to bare polyester causes faster wear of surfaces that contact the back side of the tape. This is mostly of concern with pre-1970s machines that were not designed for back-coated tapes, especially those that use pressure pads. Fortunately, there is still a large supply of old non-back-coated tape that holds up well; most types do not suffer sticky-shed syndrome the way that most back-coated stocks made from the '70s through '90s do, although early types are relatively abrasive.

To compare prices, I have made a table below of the most similar ¼" 1.5 mil stocks—one from each manufacturer—along with the lowest prices that I could find for single pancakes, not including shipping or taxes. For every company except Greencorp, this means ordering directly from the factory.

| Factory: | Type: | Form: | Price (USD): | Price per 100' (USD): |

| Astrum | А4620-6Р | 3281' (1000m) on AEG core | $35.00 | $1.07 |

| ATR | Master Tape | 2500' on NAB core | $61.00 | $2.44 |

| Greencorp | Capture 914 | 2500' on NAB core | $37.95 | $1.52 |

| RTM | SM911 | 2500' on NAB core | $59.06 (from €55.20) | $2.36 |

| Shenzhen Modo | KL900 | 2500' on NAB core | $49.00 | $1.96 |

Note that for wider tape, ATR is slightly cheaper than RTM even when both are factory-sourced. Astrum's А4620-6Р is by far the cheapest ¼" stock, and their mystery 1" tape is about half the price of the next most expensive 1" tape (ATR), but there are concerns about quality that I will detail below.

Here are my notes regarding the quality of each manufacturer's tapes. Given how variable quality can be, this info should be taken with a grain of salt.

- Astrum: The 1000' spool of А4620-6Р that I purchased in early 2024 exhibited whitish-brown waxy shedding from the oxide on the first pass, but ran cleanly after that, with good performance. Its oxide layer showed chipping near the edge on the first several turns where it was compressed by the leader splice near the core. Its back-coating can be scraped off easily with a fingernail. Astrum's mystery non-backcoated 1" tape purchased at the same time exhibits a duller oxide surface than modern tapes, though shinier than typical '50s/'60s stocks, and I have not yet tried running it. The oxide is adhered quite firmly to the base.

- ATR Magnetics: I have not used much of these tapes, but what I have used has given me no trouble.

- Greencorp: I purchased some of the earliest Capture 914 and 930 in 2016, and these exhibit two commonly reported problems: crackling noise introduced during recording, and amplitude instability of high frequencies. My 914 exhibits much more crackling noise than the 930, and on some machines the crackling is too loud for the tape to be usable, yet on others it is almost inaudible. On both tapes, high-frequency response is audibly uneven when recording test tones, especially as compared to RTM tape, but not bad enough to be a problem for most musical recording. I have not tried more recent production.

- Recording the Masters: I have no quality complaints regarding these tapes, having used plenty of SM911 and LPR35.

- Shenzhen Modo: I have not tried their tape, but reports from Reel-to-reel Tech (Curt Palme) suggest that it is durable and indeed very similar to SM911 in performance.

Lastly, I should mention that there are many additional properties that could be compared, but which I have not due to lack of information, or because the information is difficult to quantify or generalize. These include:

- Signal-to-noise ratio. This is not just related to remanence (and hence maximum output), but also to the size, orientation, and dispersion of the oxide particles, and the design of the machine used for recording and playback. Early tapes are noisier partly because maximum output is lower, but also because the particles are larger, less uniform in size, and less evenly dispersed in the coating. An analogy is that one can draw detailed patterns in fine sand, while the same patterns would have to be much larger to have the same resolution in gravel.

- Frequency response. High frequencies are particularly affected by evenness of the oxide coating; large flaws cause "dropouts", which are brief periods of high-frequency loss. As well, when recorded with ideal bias, thicker oxide coatings record low frequencies better, while high frequencies suffer due to higher bias erasure and self-demagnetization. A "velour" effect also exists, where high frequencies are recorded slightly better in one direction than the other, due to the oxide particles laying at a slight angle relative to the coating's surface.

- Distortion. Characteristics can vary significantly depending on the design and alignment of the recorder, and even when tapes are used under ideal recording conditions on the same machine; see here for an interesting comparison of EMTEC SM900 and Quantegy GP9.

- Print-through. This is generally lower for thicker tapes. It also depends on magnetic behavior of the oxide particles, and storage conditions (especially temperature).

- Abrasiveness. This varies with tape type and its condition. Brand new tape is most abrasive, and Charles Lowman (in Magnetic Recording, 1971) has claimed that heavily used tape is also relatively abrasive due to wear of the binder. Contrary to popular belief, the best tape is not one with lowest abrasiveness, since too little abrasion causes a glaze of binder material to build up on the heads, which causes poor performance and is difficult to remove.

- Other physical properties. For instance: yield strength, chemical composition and stability of the binder glue (especially susceptibility to hydrolysis), and durability.

Recommended Reading

|